Advantages of an automatic feed system for a poultry farm

Rational and timely feeding is the basis of health, active growth and high productivity of poultry. Outdated manual feeding methods are time-consuming, do not guarantee uniform feed distribution and often lead to overspending. The modern solution to this problem is an automatic feed system - a technology that significantly simplifies daily processes on a poultry farm and increases the efficiency of poultry keeping.The VADA company supplies reliable equipment for automatic poultry feeding - from compact systems for small farms to complex solutions for industrial farms. We also provide professional installation, commissioning and service. Our systems are easily adaptable to any number of livestock and type of poultry, helping to save feed and reducing the human factor in production.

Save time and labor

There is no need to carry bags, pour feed manually or constantly monitor the feeders. The system does everything itself - you just control the process.

Minimal feed losses

The feed is fed dosed and evenly. It does not crumble or spoil. Production without excessive costs.

Better weight gain of the bird

The bird receives food regularly, without delays - because of this, it grows well.

Automated control

Sensors monitor the feed level, the automation sends a signal for dosing. You see the whole situation on the remote control or control panel.

Minimal maintenance

The systems are easy to maintain and have a long service life. From time to time, only basic cleaning and inspection are required.

Suitable for any farm

The system can be installed on a farm of any size. Everything is adapted to the specific farm.

Not sure which automatic feed system is right for your farm?

We will find the optimal solution so that your birds receive feed on time, and you save time and resources

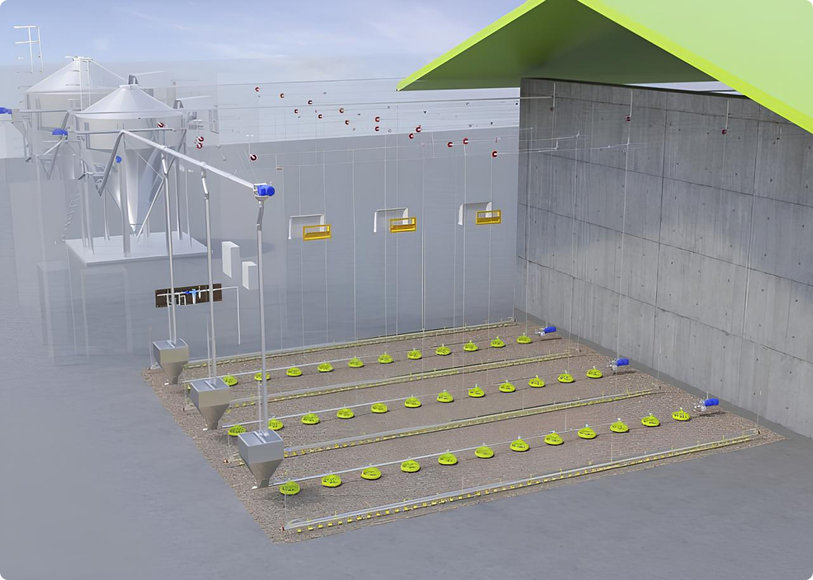

What does an automatic feed system consist of

An automatic feed system is a key element in the effective cultivation of poultry, especially broilers. It provides regular, dosed and uniform feeding without human intervention.

The equipment works according to a set schedule: feed is fed in the exact amount and at the right time. This reduces stress in the bird, the food is digested better, and the birds gain weight faster.

The system consists of a bunker or silo for storing feed, a screw or chain conveyor, feeders and feed supply lines, and a controller that automatically controls the entire process. You can additionally install sensors that monitor the feed level, set timers, or integrate the system into the overall farm management system.

Feed silo

A capacious container in which dry feed is stored before it is fed into the system. It is usually located outside the poultry house for ease of loading.Feed storage bunker

Intermediate capacity that ensures uniform feed flow from the silo to the transportation line. Stabilizes the feed pressure before feeding into the auger.Feed dispenser

Responsible for accurate portioned feed in accordance with established standards. Can be paired with a controller and weighing system for high accuracy.Electric motor

An electric motor that rotates an auger or chain in a pipe. Provides movement of feed through the system to the feeders.Pipe with auger or chain

The main highway along which feed moves. Inside is a spiral auger or chain that transports feed to the feeders.Flexible auger or spiral conveyor

Transports feed horizontally or vertically, adapting to complex room shapes. Flexible and easy to maintain.Automatic feeders

The feed is fed from a pipe into the trays, from which the bird consumes it. They are made of plastic or metal, with anti-spill sides.Suspension system (raising/lowering)

Allows you to adjust the height of the feeders depending on the age and size of the bird. Can be manual or automated.Control panel

Central control unit that controls the engine, feed schedule, sensors and automation. Allows you to optimize food consumption and system operation.Feed weighing system

Allows you to accurately control the amount of feed dispensed, helps in automated accounting. Useful for poultry farms with high requirements for rations.Feed level sensors in feeders and its residue in the silo

Determine the presence of feed in each feeding zone and give a signal about the shortage or blocking of the supply. The residue sensors monitor how much feed is left in the silo and ensure timely replenishment of stocks.Types of automated poultry feed feeding systems

The automatic feed feeding system is selected depending on the size of the farm, the number of livestock and the characteristics of the premises. There are two main types - auger and chain. Both options are effective, but have their own characteristics in installation, operation and purpose.

To make the right choice, it is important to understand how they differ.

Auger system

Ideal for small or medium-sized farms. The feed is moved by a rotating screw in a plastic or metal pipe.

Advantages: simple design, no noise, easy maintenance, affordable price

Chain system

Suitable for medium and large poultry farms. The feed is fed in a circular path using a special chain with blades.

Advantages: uniform feed, longer service life, suitable for long lines

Not sure which automatic feed system is right for your farm?

We will find the optimal solution so that your birds receive feed on time, and you save time and resources.

Implemented “VADA” projects for automatic feeding of poultry

“Karidiya” LLC, Zakarpattia

region.

LTD “Karidiya”, Zakarpattia

region.

LTD “Karidiya”, Zakarpattia

region.

LTD “RAV”, Rivne region,

Microclimate

Why is it better to buy automatic feed systems for poultry from VADA?

Need a consultation

Send a request and we will call you back

-180x100.png)