Feeding hoppers: their role in animal fattening

One of the key elements in fattening technology is an efficient feed supply system. This is where feed hoppers come in handy - special tanks for the temporary storage and distribution of feed before it is fed into the feeders.

What is the main role of feed hoppers?

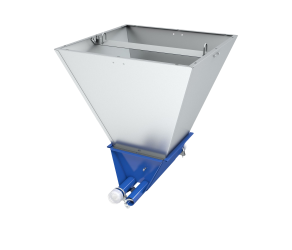

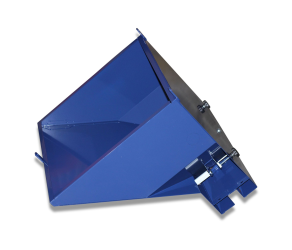

These structures help to optimize feeding processes and provide animals with stable access to nutrients. They are made of plastic, metal, there are combined - from materials resistant to corrosion and external factors. More often there are conical or trapezoidal shapes for even distribution of feed.

What are the main functions of receiving hoppers?

- First of all, storage of feed in large volumes. This is advantageous for producers who grow a large number of livestock, as there is no need for frequent replenishment of stocks.

- Reducing feed consumption saves resources: accurate feeding through bulk material hoppers reduces the risk of feed spoilage or scattering.

- Automating the feeding process: the intake hopper is connected to automatic feeding systems. This guarantees a uniform and regular supply of feed to the animals. This is especially convenient and efficient on large farms.

- Complete feed protection and hygiene: the hoppers protect grain, potatoes, vegetables from pests, level out the effects of weather conditions, and preserve the feed from spoilage and contamination.

How do I choose the right hopper?

The right hopper can help avoid feed losses and improve farm performance. One of the main criteria in its selection is the capacity, which should be matched to the number of animals on the farm and their food requirements. For example, for small farms with small livestock, you can buy hoppers from 500 to 1000 kg. Larger farms, on the other hand, can use a hopper with a capacity of several tons. A larger hopper reduces the frequency of feed replenishment.

Also, before purchasing a receiving hopper, it is necessary to take into account the space on the farm. The manufacturers of these structures have taken care of this and offer different types of feed hoppers. Vertical ones are more compact and tall, conical in shape to ensure uniform feeding. Consequently, they are suitable for farms with limited space. They allow an impressive volume of feed to be stored in a relatively small area.

Horizontal hoppers are wider and shorter, making feed access and maintenance easier.

Mobile structures are equipped with wheels or a transport system, so they can be easily moved around the farm. This solution is more suitable for large livestock farms where it is necessary to change feeding locations. They can be either vertical or horizontal.

Some receiving hoppers are equipped with automatic feed systems, which allows you to precisely regulate the amount of food for each group of animals. In addition, it is possible to control the humidity inside, which ensures optimal feed storage conditions.

Selected modern hoppers are connected to digital systems. This helps the producer to monitor feed levels and control costs in real time.

The feed fed to the animals also influences the choice of hopper. If it's a hopper for grain, mixed feed, standard designs with smooth feed are better suited. Receiving hoppers for vegetables, potatoes or pellets are equipped with powerful mechanisms and have a reinforced design.

Why is it beneficial to buy receiving hoppers from Vada?

Vada is about reliability, choice, quality and affordability. The company offers a wide range of hoppers made of reliable, high quality materials that are resistant to corrosion and moisture. You can buy a receiving hopper by contacting Vada managers, who will select and offer the best option for your farm. After all, the right choice of hopper type will increase the productivity of the farm and provide animals with constant access to quality feed.

Care and operation: What do I need to pay attention to?

Proper care of the receiving hopper will prolong its service life. It is therefore important to follow certain recommendations:

- perform regular cleaning of feed residues;

- from time to time check the feeding mechanisms - conveyors and metering units, lubricate their moving parts, and replace worn components in a timely manner;

- make sure that corrosion does not corrode the hopper walls - use anti-corrosion coatings;

- do not overload the structure, as this may damage it and the feed mechanisms;

- for some materials, especially those prone to condensation, it is critical to control hopper temperature;

- when loading excessive amounts of feed, avoid sudden impacts;

- periodically check material level or weight sensors for accuracy to avoid incorrect readings;

- routine maintenance should be scheduled, not chaotic.

Filters

Filters

-180x100.png)