Soldering equipment: everything you need for soldering

Soldering is a process used in many industries, from electronics to plumbing. To perform high-quality work, you need special soldering equipment that ensures the accuracy, reliability, and durability of connections. Let's take a look at what soldering equipment consists of, what types of equipment exist, how to use it, and how to choose the right tools for different tasks.

What is included in soldering equipment

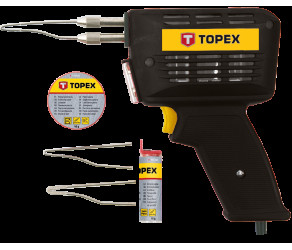

Soldering equipment is a set of tools and materials used to connect metal or plastic parts using solder. The main components:

- An electric soldering iron is the main tool that heats the solder to the desired temperature.

- A soldering station is a more sophisticated device that allows you to adjust the temperature and use different nozzles.

- A gas soldering iron is an autonomous tool that runs on gas fuel.

- Solder and flux - materials that ensure high-quality connection of parts.

- Additional accessories include soldering iron stands, sponges for cleaning the tip, and heat-resistant mats.

Soldering equipment is used in various fields, including electronics repair and plumbing installation. Even in creative projects, such as jewelry making, you will need a soldering kit.

Types of soldering equipment: how to choose the right tool?

To perform soldering work, you first need to choose and purchase the right tool and the right accessories. You can buy a soldering kit, which is a complete set that includes a soldering iron, solder, flux, stand, and other components. You should choose kits depending on the type of work to be performed:

- For electronics, sets with thin tips and adjustable temperature are suitable.

- Plumbing is handled with powerful soldering irons and special tools for plastic pipes.

- For household repairs, it is better to choose universal sets.

There are many types of soldering equipment, and in order not to buy something unnecessary, you should immediately decide what exactly you need to do a particular job.

Soldering station

A soldering station is a professional tool that allows you to precisely adjust the temperature and use different nozzles. Its advantages include:

- Temperature control for working with different materials.

- The ability to change the tip for different tasks.

- Convenience in long-term work due to stable heating.

To set up a soldering station, it is important to consider the type of solder and the material you will be working with. When it comes to microcircuits, a temperature of about 300 degrees is required, and for thick wires, 400 degrees is needed.

Gas soldering iron

Gas soldering irons are self-contained tools. They run on gas fuel. The advantages include independence from electricity, compactness, and ease of transportation. You can use a gas soldering iron even in the field, where there is no access to the power grid.

Cordless soldering iron

Cordless soldering irons are mobile tools that run on battery power. Their feature is ease of use. These models do not have any wires and heat up quickly. A cordless soldering iron is suitable for working in confined spaces.

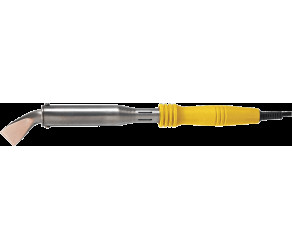

To install plastic pipes, you can't do without using special soldering irons that heat the pipes to the melting point. Typically, a soldering iron for plastic pipes has a power of 800 to 2000 watts and nozzles for pipes of different diameters.

To work with microcircuits, you need a tool with a thin tip and precise temperature control. It is very important that the chip soldering iron provides high accuracy and does not overheat sensitive components.

How to work with soldering equipment correctly?

Working with soldering irons requires compliance with certain safety rules. Firstly, you should wear heat-resistant gloves, and secondly, you can only work in a well-ventilated area. Thirdly, avoid contact of the hot tip with the skin as much as possible to avoid burns.

Before starting work, prepare the surface: clean it from dirt and oxides, choose the appropriate solder and flux depending on the material. Using a soldering station requires certain preparation steps:

- Turn on the station and set the desired temperature.

- Select the nozzle that best suits your task.

- Apply flux to the surface to be joined and melt the solder.

Be sure to fill the gas soldering iron with fuel before working. After that, just turn it on, adjust the flame, and you can start soldering.

Solder and flux: what is important to know?

To perform high-quality soldering work, you need to familiarize yourself with all the nuances that accompany it. There are several types of solder:

- fluxed solder - provides a better connection and protects the surface from oxidation;

- flux-free solder - used for clean surfaces;

- for copper and aluminum joints - have different composition and melting point.

The right choice of solder ensures the strength and durability of the connection. For example, for electronics, it is better to use solder with a low melting point to avoid damage to components.

Selection of soldering equipment in the VADA online store

The VADA online store offers a wide selection of soldering equipment. The catalog contains many popular models of soldering irons - from simple electric soldering irons to professional soldering stations. Both beginners and professionals can choose ready-made soldering kits. Gas and cordless soldering irons are designed to work in difficult conditions where there is no access to the power grid.

If you need a soldering tool, visit the website of the VADA online store. There is a large assortment of soldering irons, solder, and you can order any product with delivery in Ukraine. If you need advice, please contact our expert managers for help. Quality assurance for all types of equipment.

Filters

Filters

-180x100.png)