Plucking machines

Technology is increasingly being developed in farming, replacing routine work by staff with machines. When it comes to processing poultry, perhaps the most difficult stage is plucking. This is where plucking machines come in handy, cleaning the carcass carefully, quickly and with minimal loss.

Plucking machines from the VADA online store allow you to process poultry quickly and safely, reduce manual labour and maintain the quality of the carcasses. Order poultry equipment and automated solutions for farms — delivery throughout Ukraine, warranty and professional consultation included!

Plucking machines — effective solutions for cleaning poultry from feathers

What is important in such equipment? Primary processing of the carcass is accelerated while preserving the quality of the skin and the marketable appearance of the product. The main function of such a machine is to mechanically clean the carcass using a rotating drum and elastic rubber ‘fingers’ that separate the feathers without rough friction or scratches.

The plucking machine is suitable for various types of poultry: chickens, broilers, ducks, geese, turkeys and even turkeys. The well-tuned operation of this device preserves the marketable appearance of the carcass, minimising manual labour.

Where are plucking machines used?

These machines are, of course, most beneficial for industrial poultry farms. Since the volume of work is large, these devices can clean dozens or even hundreds of carcasses per hour. Smaller farms often use compact vertical or tabletop models. They are easy to maintain, convenient and quick to do their job.

Poultry processing companies use professional automated systems that are integrated into the overall production flow: slaughter, scalding, plucking, gutting and cooling.

What does a plucking machine consist of?

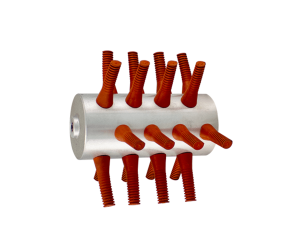

The main elements of this machine are:

- a stainless steel or durable plastic body;

- a rotating drum or disc that rotates the carcass and ensures intensive contact with the plucking elements;

- rubber ‘fingers’ – elastic elements for removing feathers;

- an electric motor that drives the drum;

- a water supply system that washes the feathers and keeps the working chamber clean.

How does a feather removal machine work?

The process itself is simple. The scalded poultry carcass is sent for plucking. It is placed in a rotating drum, where rubber ‘fingers’ gently touch the surface of the skin. The feathers are removed by a quick mechanical method without excessive pressure.

Water continuously flows into the drum and washes away the plucked feathers. As a result, you get a clean carcass in a matter of seconds.

Types of plucking machines

Plucking machines are distinguished by their method of operation and purpose.

The first type includes vertical drum machines, which are the most common and versatile because they are suitable for most types of poultry and are easy to use and maintain, and horizontal (tabletop) machines, which are smaller in size and convenient for plucking quails, chickens and young birds. Vertical plucking machines also include industrial automated lines in production facilities, which are characterised by their productivity.

Feather plucking machines are classified by type of poultry:

- standard models with conventional ‘fingers’ are suitable for chickens and broilers,

- stiffer and reinforced ‘fingers’ are used for geese and ducks, which cope well with dense feathers;

- and for turkeys, powerful, large machines with the appropriate diameter and dimensions are used.

Advantages of feather plucking machines

For poultry farms and large farms, such devices:

- reduce the time required to process poultry;

- minimise manual labour;

- carefully remove feathers without damaging the skin;

- save water and electricity;

- improve overall farm productivity and speed of production to sale.

- For poultry farmers and home use:

- process poultry without unnecessary effort;

- suitable for all small poultry species;

- compact and easy to maintain.

How to choose the right plucking machine?

Before buying a plucking machine, pay attention to its characteristics:

- productivity – how many carcasses you plan to process at a time or per hour;

- type of poultry – different types of poultry require different ‘fingers’ and designs;

- body material – stainless steel will last longer;

- engine power also affects the speed and quality of plucking;

- drum diameter: larger – more versatile;

- the availability of a water supply is very important;

- ease of maintenance;

- budget depends on the size of your farm.

Table: key criteria for choosing a feather plucking machine

| Criterion | Description | Recommendations |

|---|---|---|

| Processing capacity | Number of birds to be plucked per day | Powerful models for farms; compact models for home use |

| Type of poultry | Chicken, duck, goose, turkey | Choose the appropriate ‘fingers’ or attachments |

| Body material | Steel or plastic | Steel is more durable |

| Motor power | Determines the speed of the drum rotation | From 0.5 to 1.5 kW for domestic use, higher for industrial use |

| Connection method | 220 V or 380 V | For farms — industrial options |

| Additional features | Drain, wheels, lid | Ease of maintenance |

How to care for feather plucking machines

In order for a feather plucking machine to work properly, it must be properly cared for. What does this mean?

- It should be washed regularly after each use: the drum, body and rubber ‘fingers’ to prevent the accumulation of feather and grease residues.

- Check the condition of the rubber ‘fingers’, which wear out over time: they soften or crack, and replace them in a timely manner if necessary so that the machine continues to perform its task effectively.

- Lubricate the moving parts – the electric motor and shaft.

- Adjust the water supply system so that it works without interruptions.

- Check the cable and plug for damage for safety reasons.

- After use, the machine should be stored in a dry place.

Where to buy plucking machines in Ukraine

If you are looking for where to buy poultry carcass cleaning equipment for your household or poultry farm, contact the VADA online store. The company offers a wide range of poultry farming equipment, feather plucking machines and engineering solutions to solve any problem related to the life support of a farm of any size.

We offer a wide range of products and have a proven reputation for both the company itself and the equipment it sells. The catalogue features plucking machines that have proven themselves on farms and processing plants in Ukraine. The company's experts will advise you and help you choose the model that is right for your farm. VADA not only sells, but also installs and provides after-sales service.

The online store also sells equipment for cleaning poultry houses: high-pressure washers, steam generators, disinfectants, and everything you need for sanitising premises. High-quality cleaning equipment significantly reduces the time needed to clean a poultry house, ensuring a high level of sanitation.

Today, you can buy poultry farming equipment online — quickly, conveniently, and with professional support from specialists.

Order a plucking machine or other poultry farming equipment and increase the efficiency of your farm today!

FAQ — Frequently asked questions about plucking machines

Filters

Filters

-180x100.png)