What are pneumatic tools and compressors?

Modern compressors are an important element of technical equipment for industrial facilities and agricultural complexes. These devices provide the accumulation and supply of high-pressure air for the operation of various mechanisms. The use of compressed air allows for the automation of complex technological processes. This significantly increases the overall productivity of the enterprise.

Pneumatic energy is considered one of the safest and most efficient in the manufacturing sector. It does not create dangerous sparks during active operation of the devices. This is critically important for fire-hazardous premises or warehouses. The devices convert electrical energy into the mechanical force of air flow.

Most models of pneumatic tools on the market operate from a conventional electrical network. They provide a continuous cycle of compressed air supply to consumers. You can buy specialised pneumatic tools that connect to the system using flexible hoses. High mobility is a significant advantage when performing complex installation operations.

By investing in professional VADA pneumatic tools, you reduce personnel costs and increase production productivity from day one.

The use of compressed air covers virtually all sectors of the modern economy:

- in construction, it powers jackhammers and concrete breakers;

- at service stations, it is impossible to quickly replace wheels without pneumatics;

- the devices provide high torque for unscrewing complex fasteners.

All this saves staff time and physical effort. Every professional wants to have reliable tools at their disposal.

In Ukraine's agricultural sector, compressors are part of complex automated engineering systems. They control ventilation dampers in modern cowsheds. This allows the optimum temperature to be maintained throughout the year. Proper climate control directly affects the health and productivity of livestock. Ventilation automation reduces the risk of disease in animals.

In piggeries and poultry houses, pneumatics regulate feed delivery mechanisms. The systems operate precisely according to a set schedule without human intervention. Pneumatic drives have a long service life. This significantly reduces the farm's maintenance costs.

Pneumatic tools: advantages and areas of application

There is a wide range of tools for professional use on the market:

- powerful impact wrenches are very popular among craftsmen;

- pneumatic grinders allow you to process metal surfaces very quickly;

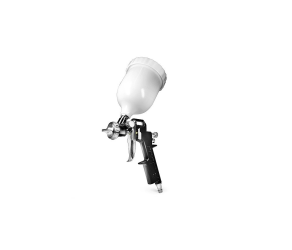

- spray guns ensure perfectly even application of paint and varnish materials or protective mixtures.

Each tool is designed to perform specific production tasks. Pneumatic staplers and nailers are indispensable for quickly assembling wooden containers. They work much faster than any mechanical counterparts. The worker expends a minimum of physical effort during the work shift. Saving working time is an obvious advantage for business. Therefore, the decision to purchase professional-grade pneumatic tools is justified.

When comparing pneumatic devices and power tools, several differences can be identified. Pneumatic tools are significantly lighter due to the absence of their own motor. This allows the operator to work longer without feeling tired. Such devices are also safe to use in conditions of high humidity. There is no risk of electric shock in pneumatic systems. The durability of the design ensures long-term operation in difficult conditions.

Advantages of using compressed air:

- No risk of short circuits.

- Highest level of fire safety in the work area.

- Ability to work effectively at significant temperature differences.

- High power with relatively small device dimensions.

- High resistance to prolonged mechanical overload.

- Minimal maintenance costs for components.

There are types of work where pneumatic equipment is absolutely indispensable. For example, when painting large areas in furniture production. Electric motors can quickly fail in such conditions. Compressed air provides constant pressure for perfect results. This prevents defects in finished products.

How to choose the right compressor and pneumatic tool?

The right choice of equipment starts with an analysis of the needs of a particular production facility. The main technical parameter is the output capacity of the device. It must exceed the total air consumption of all tools. Also, before buying a compressor, it is important to correctly calculate the required working pressure. Incorrect calculation will reduce the efficiency of the entire system.

The rated power of the motor determines the speed at which the metal receiver is filled with air. The total volume of the tank affects the frequency of automatic motor activation.

The larger the volume of the receiver, the less often the pressure switch is activated. This significantly extends the service life of the main components of the unit. Small mobile tanks are suitable for short-term work or mobile teams. Large stationary compressors are designed for workshops and farms.

Many tools require the installation of additional filters and lubricators. The lubricator provides automatic lubrication of the internal parts of the pneumatic mechanism. This prevents premature wear due to friction and metal corrosion.

Recommendations for selection:

- For domestic use, models with a receiver of up to 50 litres are suitable.

- Professional use requires a capacity of 400 litres per minute.

- A spray gun requires stable pressure without pulsations.

- Impact wrenches require a short-term high air flow volume.

- Always choose hoses with the appropriate internal diameter.

Combined power tools suitable for various tasks are often purchased for workshops. Professional carpenters prefer oil-powered models with a long service life. They can withstand many hours of daily use for many years. Reliable pneumatic tools are a profitable investment in business development.

Table: Selecting a pneumatic tool and compressor

| Type of use | Recommended tool/compressor | Main advantage | Receiver / Power | Comment from VADA |

|---|---|---|---|---|

| Domestic use | Compact compressor up to 50 litres | Mobility, lightness | 50 l | Ideal for home workshops |

| Professional construction | Powerful impact wrench, grinder | High performance, time saving | From 400 l/min | For daily intensive work |

| Painting large areas | Pneumatic paint sprayer | Perfectly even coverage | Stable pressure | Withstands many hours of use without overheating |

| Agricultural farms | Compressor for automating feed/ventilation systems | Safety, process automation | From 400 l/min, stationary | Reduces the risk of disease and saves labour |

| Mobile field teams | Small mobile compressors | Easy to transport | 20–50 l | Quick wheel replacement, minor installation work |

Where to buy compressors and pneumatic tools in Ukraine?

Reliable components are needed for the comprehensive electrification of modern farms. VADA offers a wide range of electrical solutions for farmers. The catalogue includes power cables, reliable switchboard equipment and automatic devices. Properly selected VADA electrical products ensure a stable power supply.

In addition to high-quality pneumatic tools, the website offers professional network equipment. Reliable power tools will help you quickly build or repair premises. Customers always receive an official warranty for each product purchased. The VADA range is constantly updated with the latest products. Specialists are always ready to provide meaningful advice to buyers.

You can buy a compressor and other necessary equipment on the official website of the VADA online store. The company's managers will help you choose the best model in terms of price and quality.

Filters

Filters

-180x100.png)