Motors for poultry and farms: main types and principles of operation

Electric motors are an important element of automation in modern poultry and agriculture. They ensure the smooth operation of ventilation systems and help maintain an optimal microclimate in poultry houses and farms. Motor-based fans regulate temperature, humidity, and ammonia levels, thereby reducing stress in animals and increasing productivity.

In automatic feeding systems, motors drive conveyors and augers. In watering lines, motorized pumps maintain a stable water pressure, eliminating interruptions. Reliability and energy efficiency of motorized equipment directly affect the economy of the farm, help reduce costs, and improve product quality.

Main types of engines

Different types of engines are used in agriculture and poultry farming to automate processes. Electric motors, gear motors, and mechanisms for servo drives differ in power, design, and operating principle, and are adapted to specific tasks. The right choice of motor determines the efficiency of equipment, energy consumption and stability of production processes.

Electric motors

Electric motors in poultry and agriculture play a key role in automating processes and ensuring the stability of equipment. The principle of their operation is based on the conversion of electrical energy into mechanical energy, which allows them to drive fans, pumps, conveyors and other devices.

In microclimate and ventilation systems, motors provide air circulation, maintaining optimal temperature and humidity conditions for animals. In automated feeding systems, electric motors drive conveyors to distribute feed evenly. In watering systems, they are responsible for water supply by regulating the pressure. The main advantages of using electric motors are:

- high energy efficiency

- reliability;

- minimization of human intervention.

These advantages of the mechanism can significantly reduce operating costs. Special equipment based on electric motors can significantly increase productivity.

Gear motors

Gear motors perform an important task in the automation of agricultural and poultry processes. Their role is to provide precise control over the movement of mechanisms.

Thanks to the gearbox, the engine speed is reduced and the torque is increased: such nuances are critical for conveyors, feeders, ventilation systems, and lifting mechanisms. Gear motors are used in farms:

- cylindrical

- worm motors;

- planetary.

Each model is suitable for different tasks. A cylindrical gear motor is used in conveyor belts and fans, a worm gear motor is used in lifting and turning systems, and a planetary gear motor is used in powerful units with a high load. The use of gear motors reduces equipment wear, minimizes energy losses and increases the efficiency of automatic systems.

Electric motors for servo drives

Electric motors for servo drives provide precise and dynamic control of the movement of mechanisms: they are indispensable in automated poultry and livestock systems. Unlike standard motors, these models are equipped with feedback sensors that allow you to adjust

- speed

- torque; and

- position with high accuracy.

This is especially important for automatic feeding lines, where there can be no interruptions and no overruns. The drive of servo systems ensures stable control of feed and water supply.

Ventilation systems with servo drives quickly adjust the air flow to maintain a stable microclimate. In milking machines, such a drive ensures smooth operation of the mechanisms, reducing stress in animals. The main advantages of electric motors for servo drives are:

- high energy efficiency;

- precise control;

- durability.

The mechanism optimizes processes. This reduces operating costs.

How to choose an engine, gear motor?

When choosing an engine or gear motor for agriculture, several key parameters are taken into account that affect the reliability and efficiency of the equipment as a whole. Let's consider what is important:

Power - must match the load. A weak engine will quickly overheat, while an overpowered one will increase power consumption.

Type of drive - selected depending on the mechanism. Asynchronous motors are suitable for continuous processes, while servo drives are better for precise position control.

Energy efficiency is critical for reducing operating costs. Prefer motors with high efficiency and energy efficiency class IE3 or IE4.

When choosing motors for ventilation systems, it is important to consider power and frequency control, which will allow you to adjust the speed depending on the need for air exchange. It is also necessary to evaluate the degree of protection of the motor (IP55 and above) for operation in dusty and humid conditions.

For automated feeding and watering systems, the gearmotor must provide smooth and stable operation. Worm gearmotors are suitable for mechanisms with moderate loads, and cylindrical gearmotors are suitable for conveyors and dispensers with high loads. It is important to choose models with a reliable cooling system and a power reserve for uninterrupted operation.

How to maintain motors?

Proper maintenance of electric motors is important to ensure their durability and stability. The main attention should be paid to:

- regular inspection

- cleaning

- monitoring of operating parameters.

Dust and contaminants can impair heat dissipation, lead to overheating, and shorten motor life. Cleaning is done with compressed air or soft brushes: it is important not to damage the insulation.

Bearing lubrication is another important aspect of maintenance. Insufficient or excessive lubrication leads to rapid wear, overheating, and possible engine jamming. Manufacturers indicate the intervals and type of lubricants that should be strictly followed.

When installing the motor, it is important to align the shaft correctly and securely fasten the housing. Misalignment leads to vibrations that accelerate the wear of bearings and joints. It is also necessary to take into account the operating temperature and humidity level: for aggressive conditions, choose motors with an increased degree of protection (IP55 and higher).

The power supply must be stable, as voltage surges adversely affect the windings. Regular diagnostics of cable connections, terminals, and insulation resistance will help prevent overheating and short circuits.

In automated feeding, watering, and ventilation systems, motors operate under constant load, so it is important to control the heating of the windings and not to exceed the rated parameters. It is also recommended to use frequency converters for smooth start-up and speed control. This approach helps to reduce mechanical stress and extend motor life.

Correct installation, regular diagnostics, and compliance with motor operating modes will help avoid unplanned downtime of equipment based on it. Proper maintenance also extends the operational life of the machinery.

Why is it worth buying motors from VADA?

When choosing electric motors for agriculture, poultry farming or industry, it is important to consider both the technical characteristics of the mechanisms and the reliability of the supplier. The VADA online store offers certified motors with an official warranty that confirms their compliance with international quality and safety standards. All models are tested before shipment, so the buyer is not at risk of receiving defective equipment.

One of the advantages of VADA products is their high reliability and durability. The range includes motors with a reinforced design that are resistant to dust, moisture and temperature extremes. This is important when operating on farms. Energy-efficient models help reduce energy costs, while durable bearings and reinforced winding insulation extend the service life of the equipment.

Fast delivery across Ukraine ensures prompt receipt of goods in any region. The availability of warehouse stocks allows us to send orders without delay.

Another important advantage is professional advice from specialists. VADA experts help you choose the right engine for your application, taking into account the load, operating conditions and specifics of the equipment. Professional help makes it impossible to make mistakes when choosing. Customer support at all stages of the purchase makes the process of selecting and installing the mechanism as convenient and efficient as possible.

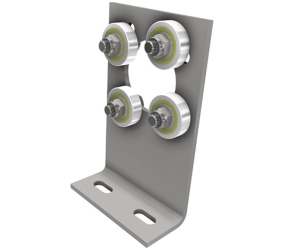

-250x250.png) Accessories for geared motors

Accessories for geared motors

Gearboxes

Gearboxes

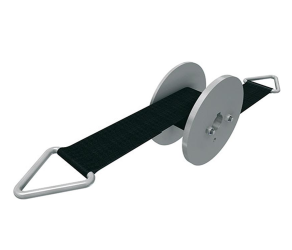

Gearmotor control systems

Gearmotor control systems

Gearmotors

Gearmotors

Lubricants to the engine

Lubricants to the engine

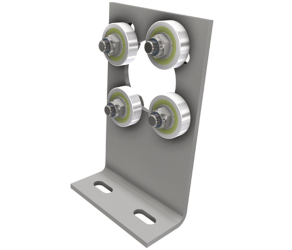

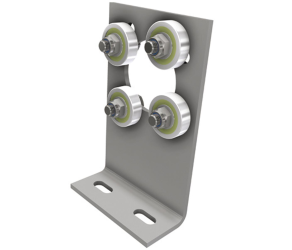

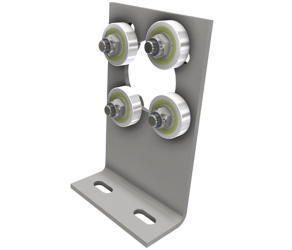

Plates for geared motors

Plates for geared motors

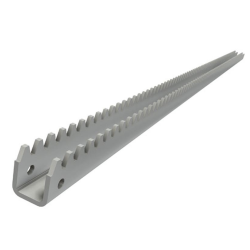

Toothed racks

Toothed racks

Filters

Filters

-180x100.png)