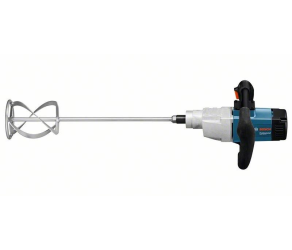

With a construction mixer, repairs become easier

A construction mixer is a powerful tool designed for effective mixing of construction and finishing mixtures, solutions: cement, putty, paint, adhesives. The use of such a device allows you to achieve a uniform consistency of materials, improves their properties, and facilitates application.

Using a mixer for construction mixtures helps to significantly reduce labor costs and speeds up the work process. The device is indispensable in construction, repair, and production.

What are construction mixers?

Construction mixers differ in the type of power supply: there are electric and battery-powered. The choice depends on the scope of work, operating conditions and the required mobility. An electric construction mixer has the following advantages:

- High power - it is suitable for thick and heavy mixtures.

- Stability of operation - this is ensured by a permanent connection to the network.

- A large selection of models - from household to professional.

We will also note some disadvantages. A construction mixer is characterized by limited mobility due to wires. This electrical appliance requires a power source at the work site, which is not always convenient.

A construction battery mixer is an autonomous device that does not depend on sockets. It is convenient when working in hard-to-reach places. Modern models with powerful batteries provide long-term operation. A battery-powered device is ideal for finishing work, activities with paints, adhesives, plasters. It is optimal for construction sites where there is no access to the power grid.

In general, electric models are suitable for stationary use. The battery-powered version of the mixer is good for mobile tasks.

What is the difference between a construction mixer and a drill with a stirrer?

The main difference between a construction mixer and a drill with a nozzle is power, design and mixing efficiency. What are the main characteristics of a construction mixer? This device is characterized by high power (from 1000 W) and copes with thick mixtures. It has a low-speed gearbox that prevents splashing. For convenience and control in operation, the device is equipped with two handles.

A drill with a nozzle has less power, and therefore is ineffective for heavy solutions, and is suitable for liquid mixtures (paint, primer). The key when answering the question - what is the difference between a construction mixer and a drill with a stirrer - will be the following: the first device is optimal for use for cement, plaster, glue, the second - is only suitable for light compositions.

Nozzles for a construction mixer: how to choose?

The choice of attachment for a construction mixer depends on the type of mixture, the intensity of work and the characteristics of the device. The correct attachment affects the efficiency of the device, the uniformity of mixing and the service life of the mixer for construction work.

Construction whisks come in spiral (left-handed, right-handed) and bladed. Left-handed whisks are suitable for thick mixtures (cement, plaster, tile adhesive), reduce the load on the engine. Right-handed whisks are intended for light and liquid compositions (paints, primers, varnishes).

Bladed whisks are universal. Such attachments are a suitable option for most construction solutions.

What parameters should be considered when choosing a nozzle?

When choosing a nozzle, pay attention to the material: durable steel with an anti-corrosion coating extends the service life. The type of attachment is important: we select threaded (M14) or for a drill chuck. Also, the more blades in the nozzle, the more effective the mixing will be.

And what diameter of the mixer is needed for different mixtures? A size of 8–10 centimeters is ideal for liquid solutions (paint, primer), 12–14 is suitable for universal mixtures (plaster, glue, putty), and from 16 centimeters - for heavy materials (concrete, cement mortars).

How to use a construction mixer correctly?

Those who are going to use a construction device in their work are often interested in the question: how long can you work with a mixer without a break? The operating time depends on the power and cooling system. Household models can withstand 10-15 minutes, then you need to take a break. Professional mixers with a powerful gearbox can work without overheating for up to half an hour.

No less relevant is the answer to the question: how to avoid splashing the mixture during mixing? You need to lower the nozzle into the mixture before turning on the mixer. You should always start mixing at low speeds and gradually increase the speed. It is also important to use the appropriate nozzle: for liquid solutions - a paddle, for thick ones - a spiral.

Safety precautions when working with a mixer

This aspect when working with a construction mixer also cannot be ignored. Consider the following:

- Securely fix the nozzle before turning on the device.

- Work in protective gloves and glasses to avoid contact with the solution.

- Hold the tool with both hands to control the process.

- Do not overload the mixer. This reduces its resource, which can lead to overheating.

The best construction mixers in the VADA online store

VADA presents construction mixers and nozzles for them from well-known brands Bosch, Makita, DeWalt, Metabo. These are reliable, proven devices with high power and durable gearboxes.

Why choose VADA? First of all, this is a guarantee of product quality, affordable prices and convenient purchase conditions. VADA offers a variety of packages: you can choose a tool with the necessary attachments and additional options. The company ensures direct deliveries from manufacturers, so counterfeits and intermediary markups are excluded.

Filters

Filters

-180x100.png)