What is a woodworking machine?

Woodworking machines are professional equipment for manufacturing various wood products on farms, in carpentry workshops and in manufacturing. Such machines are used in the production of furniture, doors and windows, and sawn timber. Raw materials are processed on the machine: cut, planed, milled and drilled.

Woodworking machines combine cutting tools and rotating mechanisms. There are multifunctional machines that perform several functions. Such models are called combined.

On the website of the VADA company, you can buy a woodworking machine for any type of raw material processing. Combined machines are highly productive and comply with European quality and safety standards. They are designed for sawing parts both along and across the grain. On a combined machine, you can mill with end mills, plane at an angle and with a clamping device.

Woodworking machines are used for the following types of work:

- wood processing;

- furniture manufacturing;

- building structures;

- carving;

- turning.

The use of a high-quality woodworking machine significantly increases the productivity and accuracy of wood processing. The process is automated with the help of the machine, eliminating the risk of errors that are often caused by the human factor. Modern machines are equipped with technological working parts — special cutting tools and precision guides. All operations are performed with high precision, allowing you to achieve perfect surfaces.

The advantages of using machines include speed of operation thanks to automation and continuous processing of large volumes of wood. One machine can combine several functions, and the precision of cutting the material optimises costs.

Woodworking machines are used in poultry and livestock farming for repair work on farm premises. They are also used in the construction of farm buildings, pens, and fences. The machines are used for cutting wood, plasterboard, and plastic.

Types of woodworking machines

Equipment for processing raw materials is classified according to its purpose, specialisation, and versatility. The main types of machines are:

- a wood lathe designed for processing cylindrical parts;

- combined woodworking machines combine various functions, saving space and time;

- special machines are used for milling, planing and grinding.

When choosing a machine, it is necessary to consider what specific tasks will be performed. Depending on the method of surface processing, there are single-sided machines such as jointers and double-sided machines (planers). Four-sided machines are designed for the manufacture of profiled parts or skirting boards.

Comparison of woodworking machines by type of application

| Machine type | Main operations performed by the machine | Who the machine is suitable for |

|---|---|---|

| Combined woodworking machine | Sawing, planing, milling | Farms, workshops, service stations |

| Wood lathe | Machining of cylindrical parts, threading | Carpentry workshops, furniture manufacturing |

| Jointing machine | Surface levelling | Preparation of workpieces |

| Planer | Precise thickness planing | Serial work |

| Universal machine | Several operations in one machine | Small workshops, farms, private workshops |

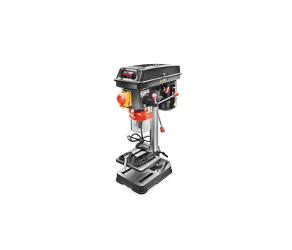

A universal machine with several functions — drilling holes, sawing, milling, etc. — will come in handy on farms. Such a compact machine saves space, replaces many tools, and allows you to perform all work quickly and accurately. A universal machine is suitable for small carpentry shops, professional workshops, farms, and even amateur carpenters.

How to choose the right woodworking machine?

To choose the right woodworking machine, you need to consider the type of work and production volume. Also pay attention to the following characteristics:

- power — 3000 W for production, no more than 2200 W for domestic use;

- presence of motor overload protection;

- structural stability;

- machine dimensions and transportability, for example, to construction sites;

- processing material;

- protection against accidental start-up;

- accuracy.

When choosing, decide on the purpose of the machine: for domestic use or professional application. In small workshops, combined or tabletop models are suitable for small jobs, saving space and money. Manufacturing requires powerful machines that can withstand high loads. Such machines can operate continuously for long periods of time, are reliable and provide high precision.

To work with tabletop tools, it is worth purchasing a convenient and multifunctional workbench. Such a specialised stand can withstand loads of up to 100 kg, and the work surface is equipped with holes for attaching tools. The table is easy to move thanks to its wheels and is conveniently secured by a swivel mechanism with a pedal.

A high-quality lathe will ensure the production of specialised parts, furniture and souvenirs.

The model has a sturdy metal construction that is reliably protected against corrosion. Five spindle speeds allow you to process any type of workpiece.

If you are planning to buy a woodworking machine for a farm or workshop, VADA specialists will help you take into account all the technical nuances — from power to operating conditions.

Caring for woodworking machines

Regular maintenance is critical for safety and quality of work. Proper operation and regular maintenance significantly extend the service life of machines and ensure safety. How to care for a woodworking machine:

- regular cleaning of dust and chips is necessary;

- moving parts need to be lubricated;

- checking the working elements will allow you to identify malfunctions and eliminate them in a timely manner;

- cutting elements need to be sharpened;

- it is important to ensure stable power supply and grounding.

After completing work, be sure to clean the machine with a brush. Sawdust and other debris, dirt and dust must be removed from all parts of the machine. This will eliminate the risk of corrosion of the guide rails.

Regular lubrication of mechanisms ensures smooth operation and reduces wear. Sharpening cutting tools will protect workpieces from damage and prevent possible accidents.

When working with woodworking machines, safety precautions must be observed. Preparation includes checking the protective covers, and operations can begin when the machine has reached the required speed. Always use auxiliary devices such as pushers and clamping elements. If a malfunction is suspected, immediately turn off the machine and disconnect the power supply.

Where to buy a woodworking machine in Ukraine?

You can buy a woodworking machine at a bargain price on the VADA website. The catalogue offers a wide range of products: woodworking machines, woodworking tools, wood lathes, and combination machines.

Advantages of buying on the VADA website:

selection according to your tasks — we will help you choose a machine for your farm, workshop or production facility:

- direct deliveries from manufacturers;

- guarantee of quality and reliability;

- professional advice and assistance in choosing;

- delivery throughout Ukraine and the option of self-pickup.

If you are not sure which woodworking machine is right for you, contact VADA managers, and we will select the optimal solution.

Power tools and electrical goods are indispensable for farmers working in poultry houses and livestock complexes. On a farm, it is necessary to constantly maintain the safety and continuity of processes: feeding, heating or cooling, ventilation systems, sanitary measures and cleaning of premises. To maintain equipment, it is important to have all the necessary tools at your disposal.

Woodworking machines are useful for building pens, fences, making cages and other important elements for animal and bird life support systems.

Order a woodworking machine from VADA — get professional equipment, expert advice and reliable service.

Improve the efficiency of your workshop or farm today!

Filters

Filters

-180x100.png)