In today's world, technological progress requires not only improvements in the equipment itself, but also in the methods of its installation and fixing. Fastening and suspension systems play a critical role in ensuring the safety, reliability and functionality of any equipment - from household appliances to industrial plants.

What are the advantages of mounting and suspension systems?

One of the tasks of the fastening and suspension system is to guarantee safety both for the installations themselves and for the personnel who service them or are nearby. A properly selected system ensures the stability of the equipment during operation; protection against falling or shifting during operation or repair; and the possibility of safe access to the equipment for maintenance.

For example, in ventilation systems or electrical networks, the use of unreliable fasteners can lead to serious accidents, such as short circuits or damage to the systems due to mechanical displacements.

Choosing the right fastening system, including feeding systems, helps ensure accurate installation of equipment, which is especially important for technologically complex installations. Fastening systems have a direct impact on the service life of the equipment. Unreliable or poor-quality fasteners can cause damage to equipment due to vibrations, displacements, or corrosion. On the contrary, properly selected fasteners that take into account the specifics of the operating environment (humidity, temperature, chemical aggressiveness, etc.) help to avoid premature breakdowns and reduce repair and maintenance costs.

Which mounting and suspension system should I prefer?

The mounting system plays an important role in organizing the reliable installation and operation of various equipment. Depending on the needs and specifics of the object, different approaches to fastening are used: fixed, suspended and combined systems.

Fixed fastening systems are a type of fastening that provides a permanent and fixed connection between a structure or equipment and a surface. Once installed and fixed, such systems do not allow for positioning or adjustment without dismantling.

Suspended systems are used to attach heavy elements to the ceiling or overhead structures and are suitable for static, permanent installations where high reliability and strength are required. They are best suited for heavy equipment that does not require regular movement. These can be cables, chains, or special holders that distribute the load and provide resistance to vibrations.

Combined lashing systems are flexible solutions that combine elements of fixed and movable (adjustable) lashing. Such systems allow you to change the position of the equipment or partially move it, adjusting the location depending on your needs.

The material of the fastener is also important to ensure the durability and reliability of the installation. The most common are steel (provides high strength and resistance to mechanical stress, suitable for heavy structures), stainless steel (used in conditions of high humidity, chemical activity); aluminum - in electronics and lightweight structures; plastic is suitable for fastening lightweight elements.

In the current difficult situation with energy supply, alternative types of energy are becoming increasingly important. Solar panels are worth mentioning here. There is a wide variety of roof and ground mounts. With their help, you can set the right direction and the optimal angle of inclination of the solar panels. It all depends on the right choice of solar panel mounting system.

Mounting and suspension systems from Vada - a profitable offer

All mounting systems offered by Vada are made of reliable materials that are resistant to the environment. And a wide range of products will satisfy any consumer demand. By contacting Vada, you save your time. The company's high-quality systems ensure timely delivery and long service life.

How do I maintain my fastening and suspension systems?

Successful installation and maintenance of the support and suspension systems depend on the correct selection of materials, precise installation, and regular monitoring of the condition of the fasteners. Timely maintenance and adherence to safety recommendations will help to avoid emergencies and extend the life of the equipment.

- Periodically check the condition of the fasteners and suspensions, especially in conditions of constant loads, vibrations, or aggressive environments. Look for signs of wear, corrosion, or loosening of fasteners.

- Cable suspension systems can lose tension over time. They should be adjusted periodically to ensure structural stability. The cable suspension system is designed for mounting objects with adjustable height. The cable suspension on the cable is performed by specialists in accordance with the current technical standards. To suspend the cable on the cable, we use fasteners also provided for by technical standards and the project: clamps, steel strips with buckles, galvanized sheets. Cable suspension on a cable is part of the installation work. In this case, the cable suspension for the cable can be performed before it is tensioned and secured (on the ground) or after the cable is fixed at a height.

- If you notice any signs of deformation or damage to the fasteners (e.g. cracks or corrosion), replace the damaged elements immediately.

Cable and ropes

Cable and ropes

Equipment winches

Equipment winches

Métis

Métis

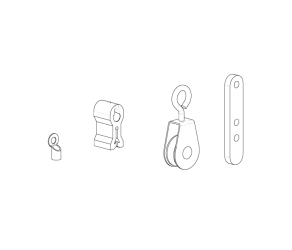

Mounting adapters

Mounting adapters

Pulleys and suspension rollers

Pulleys and suspension rollers

Related products of fastening systems

Related products of fastening systems

Filters

Filters

-180x100.png)