Bunker scales: what is important to know

Do you think that feed is being distributed correctly, but the animals' weight gain does not meet expectations? Perhaps the problem is not with the feeding itself, but with its accuracy. Bunker scales are a simple solution that allows you to control the weight of each batch of feed or grain down to the kilogram. They are an important part of the animal feeding system, as they ensure accurate dosing and accounting for feed consumption. We explain why this is so important below. You can buy this indispensable tool in the VADA online store — take a look and you will be surprised by the range on offer.

What are bunker scales needed for?

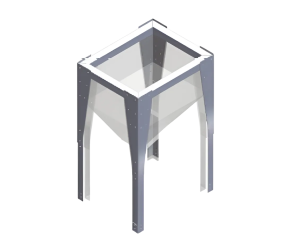

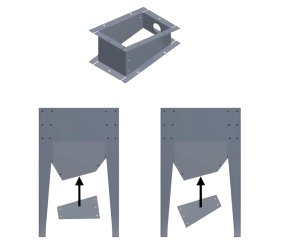

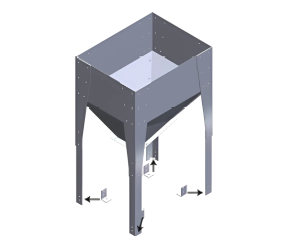

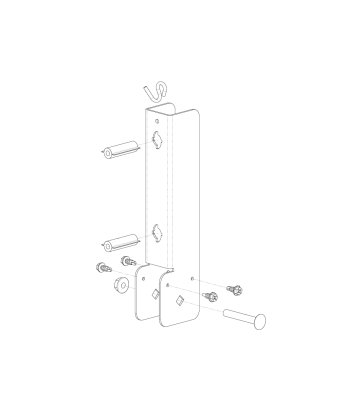

In appearance, it is a metal or plastic hopper mounted on strain gauges that constantly record the change in weight. In automated feeding systems, this equipment performs several critical functions:

- precise dosing of feed, and the farmer has an understanding of how much is coming into the feeder. This allows you to avoid both shortages and overspending;

- consumption control: if the system records deviations from the norm (for example, the bird began to eat less than usual), this may be a signal of health or microclimate problems;

- balance accounting - the scales show how much feed is left, which allows timely organization of supply.

Bunker scales are used on all farms for raising various animals and poultry. Because in combination with software, they are a powerful analytical tool: you can see consumption trends, evaluate the effectiveness of rations, and forecast purchasing needs.

Advantages of bunker scales

- High weighing accuracy - even with large volumes, the error can reach 0.1-1%;

- Automatic accounting of consumed feed — less human factor and complete analytics;

- Feed loss control — detection of theft, spillage or supply failures;

- Rational procurement planning — data on balances in real time;

- Integration into automatic feeding systems — one "brain" manages feeding, weighing and logistics;

- Possibility of remote monitoring with connection to software or mobile application;

- Reduction of staff service costs.

What are bunker scales: classification and features

Feed scales are distinguished by a number of criteria.

- For installation type they are stationary (mounted under large hoppers for centralized feed supply) and mobile (used mainly in small farms or in areas with limited space);

- For type of control — mechanical (weighing is fixed manually) and automatic (integrated with feed supply systems, signaling the minimum level and controlled by a computer or PC);

- By the number of strain gauges — single-point (for small loads — up to 500 kg) and multi-point — for heavy bunkers and high precision;

- According to the permissible load — small volume (up to 500 kg), medium (from 05 to 2 tons) and large (from 3 tons and more).

How to choose bunker scales

Be sure to consider the type of feed that will be fed to livestock. Almost all types of scales are suitable for granular or loose compound feed. Wet and mixed require scales with anti-corrosion coating and moisture-proof sensors. Microdosed additives (premixes) - here you should choose weights with a high accuracy of up to 0.1%.

In addition, take into account the volume and weight of the load: determine the maximum weight of the feed stored in the bunker. Choose a scale with a load margin of at least 20-30% to avoid overloading and ensure accuracy.

Compatibility with existing equipment is also important. Check the hopper mounts and dimensions, the type of controller already in use, and whether your system supports it.

And also availability of quality certificates. Because there are enough craftsmen on the market who can sell you a whole problem for a good picture. So choose proven manufacturers and sellers.

Where to buy bunker scales?

"VADA" company offers professional equipment for animal husbandry, in particular, bunkers for storing fodder, feeders for poultry and pigs, augers, controllers for automatic feeding lines. We have bunker scales that will provide your farm with the correct cost savings.

And our specialists will help you choose the necessary model, taking into account the characteristics of your farm. Also, quality assurance, delivery and after-sales service are all included in the comprehensive approach we apply to each project.

We don't just supply equipment - we make sure that it works efficiently, accurately and for a long time, bringing a stable result to your farm.

Filters

Filters

-180x100.png)