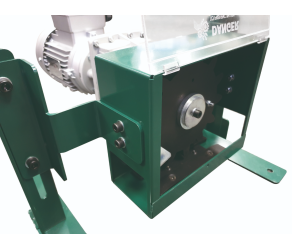

Modern farms, from small private farms to large industrial complexes, are actively implementing automation. One of the key areas is automatic feed delivery, which ensures stability, resource savings and accuracy in the process of feeding poultry and animals. For this system to work smoothly, high-quality components are required, in particular gear motors and electric motors. They are responsible for the movement of feed lines, conveyors and feed distribution mechanisms.

The choice of these elements directly affects the productivity of the farm. A reliable gear motor for feed delivery or a powerful electric motor for the feeding line ensures the stability of the system, while weak or worn-out counterparts lead to downtime, overspending and even damage to equipment. Therefore, the correct selection and timely maintenance of these units is an important investment in the development of the farm.

Gear motors and electric motors for feed delivery systems

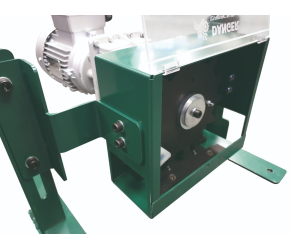

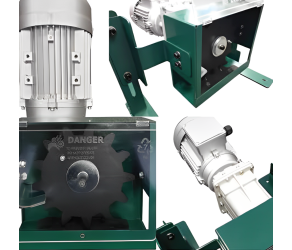

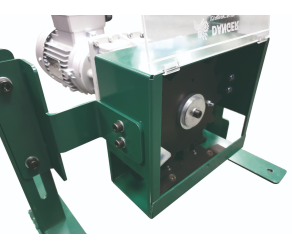

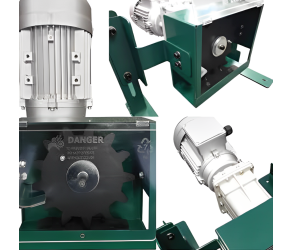

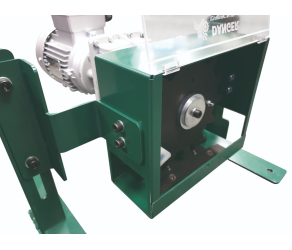

In any feed delivery system, gear motors and electric motors perform a key function – they provide mechanical movement of structural elements. These can be feed lines, screw conveyors, conveyors or dispensers that move tens of kilograms of feed every day. Without the stable operation of these components, feeding the livestock would simply stop.

Why the quality of motors and gearboxes determines the smoothness of the process:

- They operate under constant loads.

- They are often operated in difficult conditions: dust, humidity, temperature changes.

- Low-quality or worn-out motors quickly fail, causing downtime on the farm.

The consequences of using weak motors or worn gearboxes can be critical: uneven feed supply, excessive load on the line, increased electricity consumption, and the risk of mechanical breakdowns.

At the same time, modern gear motors and electric motors from reliable manufacturers have a number of advantages:

- high energy efficiency;

- protection against overheating and overload;

- long service life even in difficult conditions;

- the ability to integrate with automated control systems.

Thus, high-quality motors are the key to the continuous and economical operation of the entire livestock and poultry farming equipment system.

What types of gear motors and electric motors are used in feed supply systems

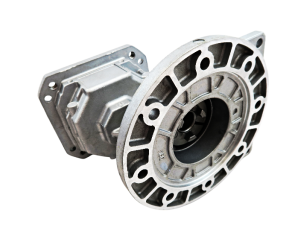

Farms use different types of gear motors and motors, which are selected depending on the specifics of the system. Gear motors for feed lines can be of the following types:

- Worm gear. They are compact and simple in design. They are quiet, have high efficiency and are often used in small feed lines.

- Planetary. Used where high power and precision are required. Thanks to their multi-stage transmission, they are capable of withstanding high loads.

- Cylindrical. Used in large farms where there are long lines and reliability is required.

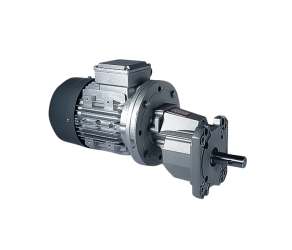

When choosing an electric motor for a feeding line, it is important to understand the different types of equipment available. Today, two types are available: single-phase and three-phase. Single-phase motors are suitable for small farms and private households where connection to a three-phase network is not possible. Three-phase motors are used in industrial complexes, where they provide more stable operation and greater efficiency.

Modern motors and gearboxes are compatible with various automatic feed lines, so they can be adapted to any system. The most common power range is from 0.25 kW to 2.2 kW. The choice of this equipment for poultry and livestock farming depends on the length of the line, the number of distribution points and the size of the farm. For example, a 0.37 kW motor is sufficient for small lines, while large complexes require motors with a power of more than 1.5 kW.

The correct selection of power is critical. Insufficient power will lead to overload and rapid wear of mechanisms, while excessive power will lead to unnecessary energy consumption and increased operating costs. That is why the choice of feed delivery equipment should be entrusted to specialists.

How to choose the right gear motor or electric motor for a feed delivery system?

For the feeding system to work reliably, it is important to consider several factors. In particular, the following parameters:

- Motor power and type. It is necessary to correctly calculate the requirements of the line, taking into account its length and load.

- Compatibility with the automatic feed system. It is important that the selected unit is suitable for the specific model of equipment.

- Quality of materials and presence of protective coating. Gearboxes and motors must have housings with anti-corrosion coating that are resistant to moisture and dust.

- Warranty and service. Purchasing equipment from a reliable supplier guarantees the availability of maintenance, repair and professional advice.

A well-chosen gear motor for feed supply or electric motor will minimise costs, avoid downtime and ensure stable operation of the farm for many years.

Where to buy gear motors and electric motors for feed delivery in Ukraine?

The most convenient solution is to buy an electric motor or gear motor from a reliable supplier. VADA offers proven equipment that meets the requirements of modern farms.

The advantages of working with VADA include:

- a wide range of gear motors and motors of various power ratings;

- compatibility with all popular feed delivery equipment systems;

- availability of additional components – screws, hoppers, controllers;

- warranty, professional advice and after-sales service.

At VADA, you can not only buy a gear motor and electric motor, but also organise a comprehensive feeding system integrated with other elements of the farm.

Not sure which motor or gearbox is the best solution for your farm? VADA experts will advise you and help you choose a unit that will ensure the efficient and uninterrupted operation of the entire feeding system.

Filters

Filters

- Сторінка

- 1

- 2

-180x100.png)