Automated animal feeding: selection and advantages of feed pipes

The key to success in animal husbandry is adherence to a set of factors that ultimately guarantee animal health and stable profits. Every farmer knows that even the best breeds, feed and technologies will not work if the right microclimate and hygiene are not in place.

This is where problems often arise, with the role of hygiene being underestimated. For example, feed residues in old pipes and dirty feeders become a source of pathogens, leading to mass disease and animal mortality. Regular cleaning and disinfection can prevent this.

VADA feed pipes automate the process, save staff time and reduce feed losses by up to 15%, allowing farmers to earn more and worry less about livestock diseases.

Feed pipes for automated feeding on farms

A feed distribution pipe is not just a piece of equipment, but rather the ‘heart’ of automated feeding. It continuously feeds from the silo to the feeders, saving staff time, distributing food evenly among the entire livestock, and reducing feed losses.

Thanks to them, chickens lay eggs evenly, pigs grow according to schedule, and cows produce more milk. By the way, feed distribution for chickens in poultry farming allows you to feed large flocks of birds in a short time. Staff can focus on other work and do not have to spend time on manual feeding.

Feed distribution for pigs with these pipes allows you to automatically adjust the feed supply depending on the age and weight of the animals. This is important for young stock and sows. Here, even the smallest error in the feed ration can affect growth and development.

Feed distribution for cattle – here, large-diameter pipes ensure the transport of concentrates and mixed feed over long distances, for example, from the grain silo to individual sections of the cowshed.

‘Incorrect installation of pipes or the use of outdated equipment can cause blockages and even uneven feed delivery or deterioration in feed quality. Therefore, the importance of correctly selected pipes should not be underestimated,’ recommend the specialists at VADA. In the VADA online store, you can find feed pipes suitable for all types of farms.

Purpose and types of feed pipes

Feed pipes not only perform the function of transporting feed from the silo to the feeders, but also determine the quality and efficiency of the entire feeding system. A properly selected pipe ensures a uniform flow of food, minimises losses and prevents clogging, which is especially important on large farms.

The choice of pipe depends on its purpose: for poultry, pig or cattle farms, the requirements for diameter, material and line length differ.

Feed distribution for chickens, broilers and turkeys involves the use of lightweight plastic or polypropylene pipes that are moisture-resistant and easy to clean. This prevents feed from accumulating and ensures that the animals receive it evenly, which increases egg production and growth rates.

Feed distribution for pigs requires stronger pipes that can withstand mechanical stress and aggressive environments. For young animals and sows, the correct choice of pipe diameter and slope is critical, as even a small deviation from the feeding norm can affect the development of the animals.

For cattle, large-diameter pipes are used, capable of transporting large volumes of feed and concentrates over long distances. This allows several sections of the cowshed to be fed at the same time, saving staff time.

In addition to the material and diameter, important parameters are the length of the line and the completeness of the system. Excessively long or incorrectly installed pipes create feed stagnation, which increases the risk of bacterial growth and reduces the efficiency of automated feeding.

"A feed pipe is not just a piece of equipment, but a key element that determines the stability of feeding and the health of the livestock. In practice, we see that the correct selection of material, diameter and length of pipes can reduce feed costs by up to 15% and increase animal productivity," says company engineer Alexander Sakun.

Types of feed pipes

| Pipe type | Diameter | Length | Scope of application | Features |

|---|---|---|---|---|

| Polypropylene | 50 mm | 2–6 m | Chicken coops, pigsties | Lightweight, corrosion resistant |

| Metal | 60–100 mm | 3–8 m | Cattle farms, industrial premises | High strength, load resistance |

| Plastic | 40–60 mm | 1.5–4 m | Poultry farming | Flexible, quick installation |

Advantages of feed pipes from VADA

The VADA online store sells pipes specifically designed for farms, taking into account all the nuances of feeding:

- Versatile – suitable for poultry, pigs and cattle.

- Strong and durable – plastic and polypropylene are resistant to moisture, mechanical damage and aggressive environments.

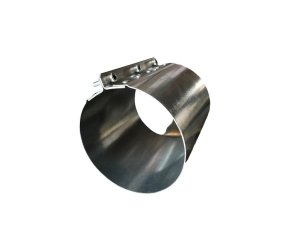

- Easy to integrate – can be easily connected to any automated feeding system.

- Precise feed delivery with minimal losses.

- Easy to maintain – easy to clean and disinfect.

How to choose a feed pipe?

The choice of pipe depends on several factors.

- Type of animals. Plastic or polypropylene pipes with a diameter of 50-75 mm are well suited for chickens, broilers and turkeys.

- For pigs, reinforced plastic or metal pipes with a diameter of 75-100 mm are suitable. And for cattle, it is worth choosing large-diameter pipes – 100-150 mm for feeding large volumes of feed.

- Feeding volumes and line length. To prevent feed from stagnating, large farms need to install pipes with a uniform diameter and optimal slope. Pipe material: plastic – lightweight, durable; metal – more durable, but requires anti-corrosion protection; reinforced – the ‘golden mean’ that combines strength with lightness.

- Compatibility with automated feeding systems – this detail is very important, so before buying, make sure that the pipe fits the existing screws, gears and hoppers. "Farmers often choose pipes based on price. But this is a big mistake that costs extra trouble later on. Poor-quality (cheap) pipes break quickly, become clogged and lose their tightness. And this carries the risk of disease and feed loss," emphasises VADA.

Where to buy feed pipes in Ukraine

As already mentioned, you can visit the VADA online store and familiarise yourself with the product range. Here you can also buy any equipment for animal husbandry. Why VADA? Because the company is a direct supplier from manufacturers, guarantees the quality and durability of goods; qualified consultants will help you choose pipes for your type of farm. We offer delivery and self-pickup — choose what is more convenient for you.

Advice from VADA experts

- Before purchasing, specify the diameter and length of the pipes for your farm. This will avoid additional costs for installation and modernisation.

- Plan the slopes and location of the pipes in advance. An incorrect angle or transition can cause feed stagnation, which increases the risk of bacterial growth and contamination.

- Install additional connecting elements and plugs so that the system can be easily cleaned and disinfected without dismantling all the pipes.

- Check the condition of the pipes regularly: cracks, blockages or wear and tear can lead to uneven feed delivery and productivity losses.

- If possible, integrate the pipes with an automated feed control system to accurately dose feed for different animal groups and reduce costs.

FAQ — for Feed Distribution Pipes

Filters

Filters

-180x100.png)