Consumables for tools are an important element of equipment operation, ensuring its efficiency and durability. Therefore, it is worth choosing only high-quality and suitable attachments and accessories. For example, for cutting – an abrasive cutting disc.

By choosing a high-quality disc, you save time and get the perfect result the first time. Buy now at VADA and get fast delivery across Ukraine!

What is an abrasive cutting disc, and where is it used?

An abrasive cutting disc is one of the most important consumables for a tool. It provides a precise, fast and safe cut without unnecessary effort, thus directly affecting the quality and efficiency of work.

This element can also be called a ‘disc’ or a metal or stone cutting disc.

What materials are processed with abrasive cutting discs:

- metal;

- stone;

- concrete;

- brick;

- stainless steel;

- paving slabs;

- sometimes ceramics (diamond discs are more often chosen).

The disc is a consumable material for the tool, because it does not ‘cut’ but gradually wears down, decreasing in size. The disc cuts due to the abrasive grains in its composition, like emery. These grains are held together by a binder (resin), which ensures the strength of the disc.

The scope of use for abrasive cutting discs is quite wide:

- construction;

- repair;

- installation work;

- metalworking;

- locksmith work;

- automotive industry;

- stone and road works.

For DIY enthusiasts and professionals, they are the ideal solution for the garage, workshop or cottage. Order now – VADA will deliver quickly!

Abrasive cutting discs are also ideal for domestic use (in the garage, workshop or cottage).

What specific tasks can be performed with abrasive cutting discs:

- cutting metal parts;

- installing gates and wickets;

- repairing car body parts;

- cutting metal blanks;

- cutting bricks;

- cutting concrete elements;

- rust removal;

- stripping welded joints;

- chamfering;

- fitting parts ‘on site’.

Abrasive cutting discs can be purchased for the following equipment: angle grinder, mounting saw, special machine tool. In other words, this consumable material is mainly used for equipment that cuts at high speeds and at high revs.

Main types and characteristics of abrasive cutting discs

It is not recommended to use the same disc ‘for all materials in a row’. A disc used for metal may not necessarily be suitable for stone.

Therefore, it is worth familiarising yourself with the different types of equipment.

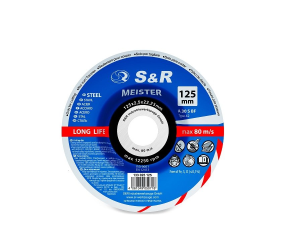

Popular sizes and purposes:

- reinforced abrasive cutting discs (diameter 180x3 mm) — suitable for medium-sized angle grinders, very durable; provide an average cut, deeper than 115-125 mm;

- 125 cutting discs — the best option for domestic and professional work, suitable for almost all angle grinders;

- 230 mm diameter discs — for deep cuts.

- For concrete and brick, you need to buy a stone disc, for metal — a disc with a thickness of 1.6-2.5 mm. If you need a quick cut, a thickness of 1.0-1.2 mm is better.

What is the main difference between reinforced and conventional abrasive discs? Reinforced discs provide strength and tear resistance. Conventional discs are less resistant to stress and can sometimes be more brittle.

The main abrasive materials and their characteristics:

- aluminium oxide – provides a clean cut, withstands loads and heat;

- silicon carbide – more suitable for stone, concrete and brick (hard and somewhat brittle materials), works less well with metal and wears out faster.

If the disc is ‘for metal’, in most cases it will be aluminium oxide.

To understand the type of abrasive, grain size and other important information about the disc, pay attention to the markings. This will allow you to choose the right consumable material.

How to choose the right abrasive cutting disc?

For reliable and effective work with abrasives, it is important to check their quality and certification.

Practical tips for the safe use of abrasive cutting discs:

- before installing the disc, it is worth spinning it for 1-2 minutes at cold speed;

- it is prohibited to work without protection – at a minimum, safety glasses must be worn;

- do not use a wheel with a diameter larger than that allowed by the tool (check the speed of the angle grinder before using the disc);

- do not press too hard on the wheel;

- Do not overheat the tool (you can gradually reduce the cutting depth during prolonged operation).

Store in a dry room with minimal humidity, away from direct sunlight.

To buy abrasive cutting discs, you need to consider the type of material to be cut, the diameter and thickness, the maximum speed and power of the tool. In addition, different brands and manufacturers may have their own characteristics, which only experienced specialists can navigate. So, to be sure of your choice, it is worth consulting with professionals.

Where to buy abrasive cutting discs in Ukraine?

The VADA online store will definitely help with the following tasks:

- buy 125 cutting discs;

- buy 125 cutting discs;

- buy abrasive cutting discs;

- buy consumables for tools.

We recommend purchasing equipment from the VADA online store, as it has many advantages.

Advantages of purchasing abrasive cutting discs from VADA:

- a wide selection of equipment for any task;

- professional support for each customer;

- only certified brands;

- fast delivery throughout Ukraine;

- optimal prices – direct contracts with suppliers.

What other consumables for tools can you choose from the VADA online store catalogue?

- drills;

- auger drills;

- saw blades;

- glue sticks;

- chisels for concrete;

- diamond cutting and grinding discs;

- diamond and metal core bits;

- drill bit and bit sets;

- ring saws;

- saw blades;

- cutters for manual tile cutters;

- drill bits for wood, metal, stone, ceramics;

- milling cutters;

- non-woven abrasive accessories;

- wire and nylon brushes.

VADA is a leader in equipment sales in Ukraine. The catalogue contains over 100,000 items! Contact us now for professional advice and services!

Filters

Filters

-180x100.png)