It has long been proven that diamond cutting discs are the most effective tool for cutting hard materials. Below, you will learn where and how to choose these indispensable household items.

Purpose of diamond cutting discs

Diamond cutting discs are circular tools with a cutting edge made of the hardest material on Earth. Diamonds are usually microscopic and embedded in the edge of the tool. This way, they do not wear out and quickly ‘crush’ the material.

The equipment is most often used for cutting concrete, stone, ceramics, granite, porcelain stoneware, asphalt, and brick. It consists of diamond powder, a bond, a steel base, and a mounting ring.

There is also an option to purchase a conventional (abrasive) cutting disc, but the diamond disc has many advantages:

- high precision;

- cleaner cut;

- much longer service life;

- better speed;

- higher productivity.

It is worth buying diamond cutting discs, as they contain diamonds that are resistant to impact and high temperatures, which ensures a long service life for the device. Abrasive discs, on the other hand, are fragile and wear out quickly. They also cannot be used to cut concrete or tiles, as they can simply burn out.

That is why diamond cutting discs play a key role in working with power tools. They do not overload or overheat them, because the disc cuts cleanly and quickly.

They are the only ones that can cut concrete, tiles, stone and granite. Without a diamond disc, most construction work would be impossible. This is the only working option and there is no alternative to it.

Where diamond cutting discs are used

The disc (diamond, cutting) has an extremely wide range of applications: from large-scale production to household tasks. It is even used in jewellery making and in the automotive industry for the manufacture and repair of cars.

Functions of diamond cutting discs in construction:

- cutting concrete, reinforced concrete, asphalt;

- separating slabs;

- road repair;

- cutting blocks and kerbs;

- preparing holes for pipes;

- processing granite.

It is not surprising that diamond discs are indispensable for this industry, as they can cut virtually all types of building materials.

It is also worth buying diamond cutting discs for farms, as they will be useful for the following tasks:

- construction of paths and livestock buildings;

- repair of cowsheds, piggeries and poultry houses;

- creation of ventilation holes;

- demolition of old structures (fences, warehouses).

The tool will ensure quick repair of agricultural equipment and infrastructure.

What types of diamond discs are there:

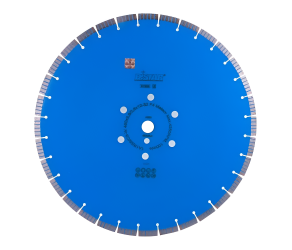

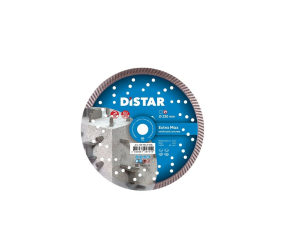

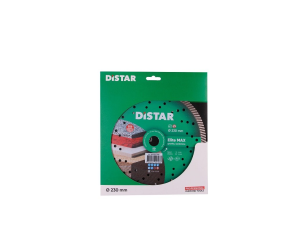

- solid – have a solid diamond edge, the cut is the cleanest and without chips, ideal for finishing work (neat tile cutting);

- segmented – the edge is divided into separate segments, between which there are cooling ‘windows’, the cut is rougher, suitable for construction and dismantling;

- turbosegmented – wavy (corrugated) diamond edge or a combination of turbo edge and segments, clean cut, suitable for mixed work.

In general, each type is universal and fulfils the main purpose – fast cutting of tiles and concrete. However, it is important to choose a diamond blade specifically for your type of work. One blade solves dozens of tasks over a large area, saving time and labour.

How to choose a diamond cutting disc for a specific tool?

What to look for when buying discs (diamond, cutting):

- the type of material to be cut – different tasks require completely different types of discs;

- diameter and mounting hole – the diameter affects the depth of the cut;

- thickness and type of cutting edge – the thicker the segment, the longer its service life, but cutting speed may be slightly reduced;

- speed and number of revolutions – for long-term use, sufficient intensity of the device will be required;

- cutting technique – oblique or straight cutting may be required.

It is also important that diamond cutting discs are compatible with other equipment – angle grinders (grinders), wall chasers, thread cutting machines, tile cutters, stationary cutting machines.

A disc for domestic and professional use are two different things. For domestic needs, it makes sense to buy a diamond cutting disc with the following characteristics:

- medium or low resource;

- diameter 115–125 mm;

- universal or ‘tile’ type;

- less aggressive cut.

Such a tool will be light and mobile in operation, providing a neat cut without excessive power.

However, for professional purposes, a completely different diamond grinding wheel is required. Its characteristics are:

- thick and durable steel base;

- large segments and protective slots;

- diameters of 125–300+ mm;

- markings Concrete, Reinforced, Hard Material, Asphalt.

Most likely, a solid disc is suitable for tiles, porcelain stoneware and minor repairs in general, a turbo segment disc is suitable for bricks and paving slabs, and a segment disc is suitable for professional work with concrete and demolition.

To know exactly which diamond cutting discs to buy, it is worth paying close attention to the brand, as this is the only guarantee of safety and accurate results.

When you buy a diamond disc from VADA, you get a reliable tool for any task, guaranteeing a clean cut and a long service life.

Care of diamond cutting discs

Storing the equipment correctly will significantly extend its service life.

- store in a dry and ventilated room, preferably vertically;

- do not stack heavy discs on top of each other;

- remove dust and material residues after work;

- regularly ‘refresh’ the diamond edge;

- do not overheat.

For safe and high-quality work, it is also important to follow the instructions:

- check the disc attachment to the tool spindle before use;

- Do not use discs with damaged segments or cracks;

- Use protective equipment: goggles, earphones, gloves and a respirator.

Overheating protection is a separate important topic for diamond discs. They all need cooling due to the high intensity of friction.

Segmented and turbo-segmented discs have special slots, waves or segments that dissipate heat during rotation. In other words, they cool themselves. However, the disc must also be cooled using additional methods – do not press on the tool, take breaks, do not tilt it and clean it of clogged material.

In summary, solid discs work better in water, while segmented and turbo discs are cooled by air but require pauses.

Where to buy diamond cutting discs in Ukraine?

To buy a diamond grinding wheel, we recommend visiting the VADA online store.

VADA is a reliable supplier of equipment for farms, poultry houses, pig farms and greenhouses.

Advantages of buying cutting discs from VADA:

- a wide range of certified products;

- consultations with professional engineers;

- fast delivery throughout Ukraine;

- quality assurance and compliance with modern standards.

In the online store VADA online store catalogue, you can buy household goods and, equally important, consumables for tools. Visit vada.ua and buy diamond cutting discs to get the job done quickly, accurately and without risk to your tools.

Filters

Filters

-180x100.png)