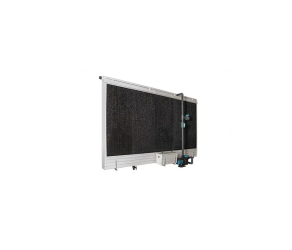

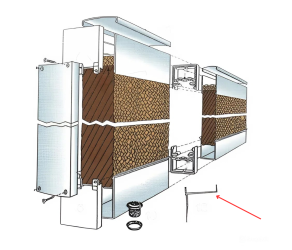

When talking about the latest cooling systems for agriculture, pad cooling immediately comes to mind. This technology lowers the temperature and humidifies the air using special panels. In particular, they are installed along the walls of poultry houses, piggeries and cowsheds. This makes the panel cooling system ideal for livestock farming.

Components for the PadCooling system

Components for the panel cooling system have quite different functions, but are equally important for farming.

When considering spare parts as an element of poultry farming equipment, their main purpose is to ensure low levels of heat stress, as poultry are very sensitive to overheating (especially broilers and laying hens). Therefore, the irrigation and cooling system must provide the most accurate control and ensure the cleanliness of the premises.

As pig farming equipment, piglet rearing components promote coolness and comfort, which increase the animals' appetite and improve their reproductive function. A high level of protection against dust, ammonia and corrosion is important here.

Evaporative cooling components are also important equipment for cattle (cowsheds, milking parlours, calf pens), as heat stress reduces milk yield. For cattle, the main thing is air exchange and stable cooling without excessive humidity, so it is important to install high-performance fans for pad cooling.

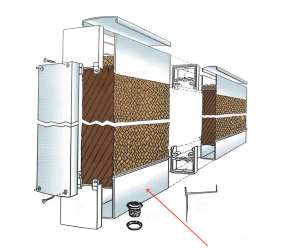

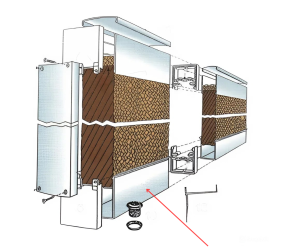

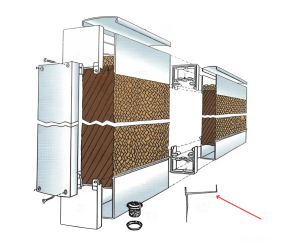

Main elements of a panel cooling system

Every complete pad cooling system must have cooling pads, pumps, fans or an exhaust system, as well as a control centre. However, it is not enough to just have the main elements – they must be combined with each other, and the components must enhance their performance. If even one of the components for evaporative cooling is selected incorrectly, the efficiency of the entire panel cooling system will drop by more than 30-40%.

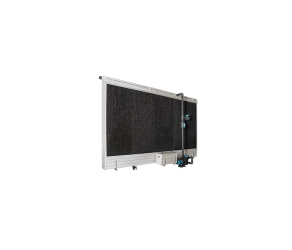

PadCool panels are the main cooling elements on which everything depends. They can be called the ‘heart’ of the panel cooling system.

Panels can be of different densities and thicknesses. They are usually made of cellulose paper, polymer and synthetic materials. When installing, it is important to choose the correct angle of inclination and coating.

Panel functions:

- absorb and distribute water;

- allow air to pass through;

- evaporate water;

- filter and trap dust.

If the operating conditions are observed, these components for pad cooling will serve the farm for a long time without leaks or deformation.

Fans ensure air circulation through the cooling panels. These components for evaporative cooling are located on the opposite side of the building from the panels.

For a panel cooling system, it is critical that air passes through the panels evenly and gradually. If you choose a fan that is too powerful or set it up incorrectly, the air will ‘skip’ without having time to cool down and will damage the panels.

Pumps and pipes – ensuring water supply for evaporative cooling.

If the pumps are too weak, the water will not reach the panels. They will dry out due to the air and will soon fail. The pump must create sufficient pressure, but not excessive pressure. Once a month, the filter and hoses must be flushed to prevent deposits from forming.

The power must correspond to the length of the panels and the number of nozzles. The material can be different, but PVC or polypropylene pipes are often chosen for farms — they are cheaper, more convenient and are not affected by moisture.

Water tanks (reservoirs) are containers in which water is stored for the panel cooling system. The volume of the tank must correspond to the area of the panels and the water consumption.

It is recommended to flush out sediment once a season. This will ensure that the water circulates steadily and the filters do not become clogged. On farms, it is better not to place the tank in the sun so that it does not heat up.

Drainage channels or trays collect excess water for reuse, so they are located under the cooling panels. Thanks to these components for pad cooling, the system will operate without flooding.

Control units – provide temperature and humidity control. Based on the indicators, the control centre regulates the operation of the pad cooling system itself, or turns it on and off according to a timer. Modern technologies enable remote and automatic control, even without human intervention.

Sensors and controllers – these are components for the panel cooling system that are responsible for monitoring temperature, humidity and starting current. They prevent excessive moisture, which can harm poultry or plants. Animals also do not overheat, as the temperature will not ‘jump’ and the system will only work when needed. This also has a positive effect on energy savings.

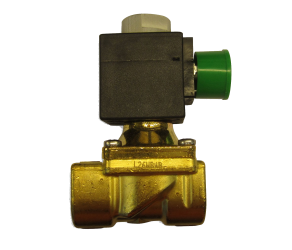

Filters and valves – prevent the system from becoming clogged with solid particles.

They can include mesh filters or sediment traps in front of the pump.

High-quality filters are the key to continuous operation. If you save on them, other elements will quickly fail. It is best to install a mechanical or disc filter at the pump inlet.

How to choose components for an evaporative cooling system?

Installing a pad cooling system is not particularly difficult, but it can take a long time if the components for evaporative cooling are not selected correctly.

When purchasing components for panel cooling, we recommend paying attention to the following parameters:

- The area and height of the room. Air must circulate and water must reach all panels.

- The number and type of connected devices. The easier it is to connect the components for pad cooling, the easier and faster the installation will be.

- Energy consumption and efficiency requirements. The panel cooling system must provide the desired effect with minimal energy consumption.

Price – although important, it is far from the main factor when choosing components for a panel cooling system. There is a risk of choosing the most expensive ones, but they may not be compatible with each other. For example, pipes, fittings and valves must be suitable in terms of diameter and pressure.

Where to buy components for the PadCooling system in Ukraine?

If you trust the professionals, your irrigation and cooling system will serve you for more than just one or two seasons, but much longer.

The VADA company has long earned the trust of farmers, as it is able to select equipment for livestock farming, taking into account the individual needs of the farm. VADA provides a full range of services covering the entire process, from design to commissioning of the panel cooling system.

Experts with many years of experience will provide professional advice before you buy components for panel cooling, and a team of specialists will help with calculations and installation.

In the VADA online store catalogue, you will find:

- control units;

- components;

- pumps;

- panels;

- pre-assembled pad cooling systems;

- pipes.

Ensure an optimal microclimate in your premises – buy cooling control units from VADA!

Filters

Filters

-180x100.png)