Microclimate control units: purpose and benefits

A stable microclimate is one of the main factors on which farm productivity and animal health depend. Regardless of whether it is a poultry house, pig house or cow house, optimal temperature, humidity and air circulation directly affect growth, feed conversion and livestock safety. This is where microclimate control units, or microclimate controllers, come to the rescue.

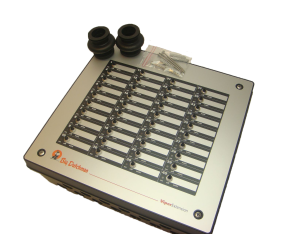

In simple words, they can be called the brain of the microclimate system, which collects data from the room, analyzes it and automatically regulates the equipment. It is necessary in all rooms where there are animals: in poultry houses, pig houses, milking parlors. The controller monitors such key parameters as temperature, humidity, ventilation, air pressure and lighting. When these systems work in tandem, then optimal conditions for keeping livestock are created on the farm.

It doesn’t just save energy: thanks to the correct operation of all equipment (fans, heaters, dampers, cooling systems), a stable microclimate for farms is achieved, which increases efficiency and reduces costs.

How a microclimate controller works

The principle of operation of a microclimate controller can be explained very simply. Imagine it as a smart monitoring center that:

- collects data from sensors on temperature, humidity, CO₂ level, air pressure and other indicators in the room;

- analyzes them to see if the conditions meet the set parameters;

- automatically controls the equipment. If the temperature drops or rises, the controller turns on or reduces heating, activates ventilation or cooling, and adjusts lighting if necessary.

Microclimate controllers can work autonomously or be connected to a remote monitoring system, which allows you to monitor the state of the farm via a smartphone or computer. For example, if the temperature in the poultry house has risen by 2–3 °C above normal, the controller automatically increases the ventilation power or opens the dampers to cool the air. If the humidity in the pig house increases, the system turns on the heating and additional air circulation to avoid condensation and the development of pathogens. The microclimate for pig houses requires precise control of temperature, humidity and ventilation to avoid stress in animals.

Types of microclimate control units

Manufacturers of equipment for poultry farming and livestock farming offer various microclimate control units: from basic models for small farms to complex systems for industrial poultry houses. They can control one or more parameters, have a different number of channels for connecting equipment and support integration with remote monitoring.

Modern industrial air conditioners and controllers allow you to not only maintain the temperature, but also create a microclimate for poultry farms, which really affects productivity and provides comfortable conditions for birds. For example, in poultry houses, stable temperature and humidity reduce stress in young animals, accelerate growth and improve feed conversion. The right microclimate for milking parlors affects stable milk production and reduces the risk of diseases in cows.

| Type | Purpose | Features | Where used |

| Basic controllers | Temperature and ventilation control | Easy setup | Small farms, poultry houses |

| Advanced controllers | Humidity, CO₂, pressure, lighting control | Remote access possible | Large pig farms, cow houses |

| Integrated systems | Complete microclimate control + feed systems | Operation via PC or smartphone | Modern livestock complexes |

How to choose a microclimate control unit

Choosing a microclimate control unit depends on several factors that must be taken into account. Let's get acquainted with them.

Type of room. A poultry house, pig farm or milking parlor have different requirements for temperature, humidity and ventilation.

The number of connected equipment. Fans, dampers, heaters: they determine how many channels the controller supports.

The need for remote monitoring. This is often critical for large farms.

The number of sensors. The more of them, the more accurately the microclimate is controlled.

And yet, does the equipment for farms of different sizes differ? Experts recommend basic control units for small farms, they will be enough. For large poultry farms, it is better to choose models with remote control and advanced functions. For milking parlors of cowsheds, the accuracy of humidity and temperature control is important, so it is better to give preference to professional controllers here. “Our experts will help you choose the optimal microclimate control unit for your farm, taking into account all the nuances,” says the company “VADA”. And competent consultation is already half the battle.

Where to buy microclimate control units in Ukraine

In Ukraine, you can buy reliable controllers and other microclimate equipment in the online store “VADA”. The entire range of equipment for livestock and poultry farming is presented here: fans, industrial air conditioners, dampers, heaters and automation systems.

The company “VADA” is a proven supplier which does not just sell equipment, but helps to choose a microclimate system for farms, configure it and ensure its effective operation. Contact “VADA”, and we will select the perfect industrial air conditioner or microclimate controller for your poultry house, pig farm or milking parlor.

Filters

Filters

-180x100.png)