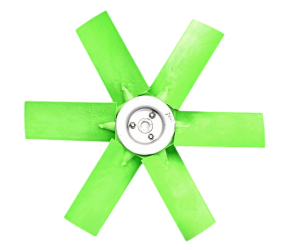

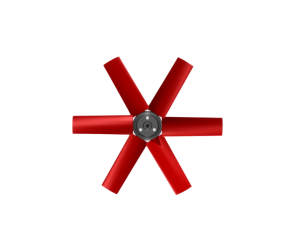

Fan blades for an industrial ventilation system: how to choose, where to buy

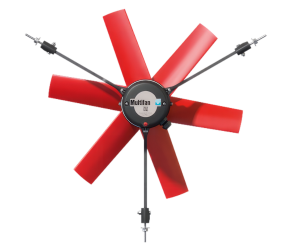

The reliability of industrial ventilation is determined by the condition of its main components, primarily the fan blades. They form an intensive air flow necessary for effective cooling, ventilation and maintaining a stable temperature on farms, in poultry houses, and production facilities. Fan blades and impellers made of durable, wear-resistant materials allow you to achieve maximum efficiency of ventilation systems in various operating conditions. Such ventilation equipment is manufactured by VADA.

Why are fan blades needed?

Fan blades are the main functional element on which the efficiency of the entire ventilation system depends. Their main task is to form and direct the air flow. It is thanks to the movement of the blades that the air inside the room circulates with the required intensity, providing ventilation, cooling or removal of harmful substances.

In industrial conditions, fan blades help to remove moisture, ammonia vapor and excess CO₂. This is important for maintaining a healthy microclimate in:

- poultry houses;

- farms;

- warehouses;

- workshops.

Thanks to industrial fans, it is possible to maintain a stable temperature regime in the room. In summer, they prevent overheating, provide excellent ventilation of farms. In winter, the equipment contributes to the even distribution of warm air. This allows you to reduce energy costs for heating.

Without the effective operation of fan components, the system will not be able to function smoothly: productivity drops, humidity levels and the concentration of harmful gases increase. This directly affects the health of animals, the condition of the equipment and even the quality of the finished product.

How to choose the right fan impellers?

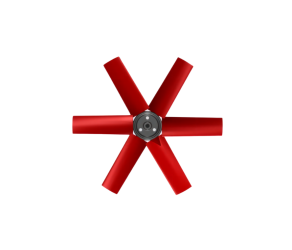

The selection of the impeller directly affects the efficiency of the ventilation system, energy consumption and stability of the equipment. The type of ventilation device is taken into account. Axial and centrifugal models have fundamental design differences.

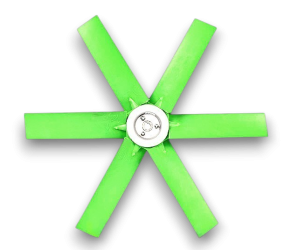

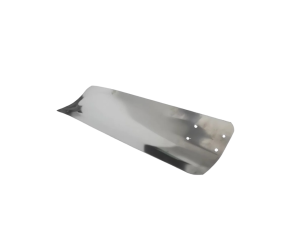

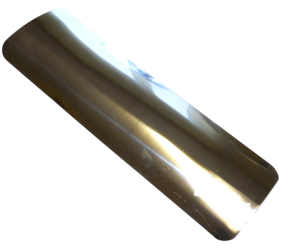

The equipment of the first type moves air parallel to the axis of rotation. Its impeller has less curved blades, similar to a propeller. The equipment is used when high performance is required at low pressure. A centrifugal fan pumps air perpendicular to the axis of rotation. Its impeller has curved or straight blades, which create higher pressure with a smaller volume of air.

The size and shape of the impeller affect the volume of air moved and aerodynamic characteristics. The diameter is selected according to the engine power and the working environment. The material of the impeller also matters:

- Aluminum - withstands high temperatures, aggressive environments and impacts. Suitable for production and livestock.

- Plastic - lightweight, cheaper, suitable for places with low load.

- Composites - combine lightness and high resistance to corrosion, ultraviolet, deformation. Ideal for industrial facilities (for example, ventilation of poultry houses).

An important parameter is the compatibility of the impeller with the model of the ventilation device: shaft diameter, type of fastening, rotation speed. An incorrectly selected impeller leads to engine overheating or reduced efficiency.

The VADA online store offers a wide selection of impellers for ventilation equipment of all types. Specialists will help you choose the best option depending on the conditions of use: ventilation of farms, poultry houses, warehouses, industrial workshops.

Blades for an industrial fan: where to buy in Ukraine

You can buy industrial fans from VADA. It is also a leading supplier of components for ventilation equipment. We offer a wide selection of components for ventilation systems: blades and impellers of various types and diameters. The company guarantees:

- individual selection of components according to the client's parameters;

- quality of certified products;

- professional advice from engineers.

VADA also provides fast delivery of goods across Ukraine. If you buy fan blades from VADA, you will get reliability, efficiency, and uninterrupted operation of ventilation systems.

Filters

Filters

-180x100.png)